Installation

Inspect the gauge structure before removing from the moulded clear plastic packing. Report any obvious damage to your AML Distributor before opening the moulded packing. Save the packing material, including the small foam plastic piece which restrains the flange in the mould.

It is assumed that the user is familiar with the use of Conflat® flanges and copper gaskets. Appropriate handling techniques must be used to avoid contamination of the gauge head. Avoid straining the feedthrough pins, as this may cause a leak.

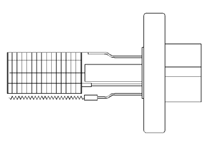

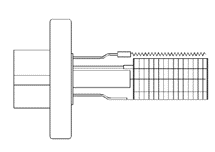

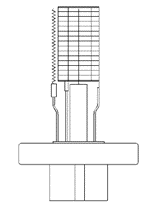

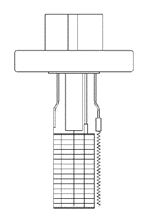

Mount the gauge head in a position where the free electrons generated in its vicinity will not affect other equipment. The gauge head is intended to be inserted so that the entire grid structure is inside the chamber: should any part of it remain inside the tube behind the mounting flange the sensitivity of the gauge head will be altered. The orientation of the gauge head should be such that the filaments are to the side of, or below, the grid structure. This will ensure that if the filament should sag or break it will not short-circuit to the grid. It is desirable that the feedthrough pins point sideways or upward so that the weight of the connector and cable do not tend to pull the connector off the pins.

|

|

|

|

| No | Yes | Yes | No |

The performance of the ion gauge may be affected by other electron or ion generating processes within the vacuum chamber: should shielding of the gauge head be necessary, ensure that the conductance between the gauge head and volume of interest is not significantly decreased by its presence. Any grounded shield will affect the electron dynamics in the gauge head and hence its sensitivity: this can be minimised by locating the shield as far away as is convenient.

When this gauge is used in conjunction with an AML NGC3 Ion Gauge Controller, both the gauge and controller are protected from all normal failure modes of either. Users should be aware of potential hazards from other equipment, however, particularly those introducing high voltages into the vacuum chamber (X ray sources for example). As a direct discharge from one of these at high pressure may cause extensive damage, shielding should always be introduced in such cases.