Installation

Before installation

WARNING: Read this manual carefully before installing and operating the SMD4. Observe the following safety instructions.

Qualified personnel

WARNING: All work described in this document may only be carried out by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product.

WARNING: Without proper training and necessary experience, damage to the equipment or personal injury might result.

DANGER: Danger of electric arcing! Never plug or unplug any connector while powered. Plugging or unplugging a motor while powered may damage or destroy the driver output stage.

Additional safety and warning notices.

Unpacking

On receipt of the instrument remove all packing material and check that all items on the delivery note have been received. Report any damage or shortages to the company or distributor who supplied the instrument. The packing material has been specially designed to protect the instrument and should be retained for possible future use.

Mechanical installation

The SMD4 is a freestanding instrument. It does not require mounting. Forced air ventilation is not required. The ambient operating temperature range is 10 °C to 60 °C.

Connecting

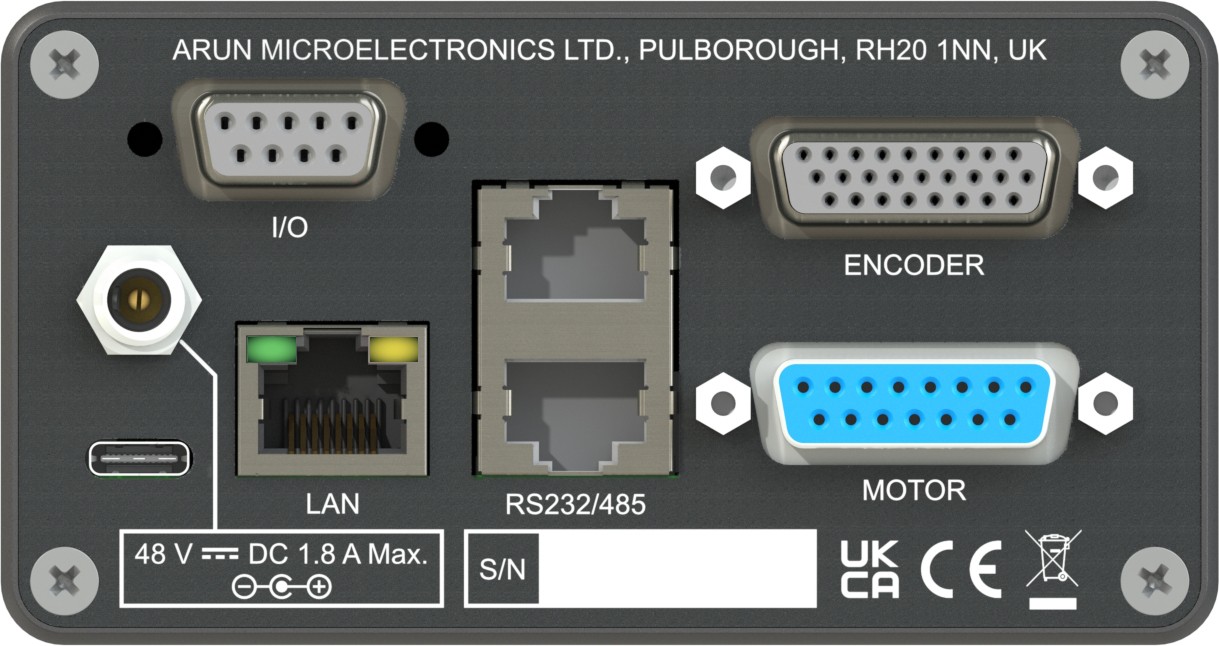

Rear panel

Power

|

Connector: Barrel power jack 2.1 mm pin, 5.6 mm hole |

||

|

|

48 Vdc input. Centre positive. |

|

Power input for both internal logic circuits and the motor itself.

The power supply must:

- Meet the requirements set out in the technical information section of this document

- Provide reinforced or double insulation between mains and supply output

DANGER: Danger of electric arcing! Never plug or unplug the connector while powered.

CAUTION: In the event of reverse polarity, a short circuit will occur between GND and V+ through an internal power diode. An external fuse may be required.

The fuse should be sized:

- Greater than the current consumption of the SMD4 when operating the connected motor

- Less than the maximum current output of the power supply

- Considering the voltage of the supply

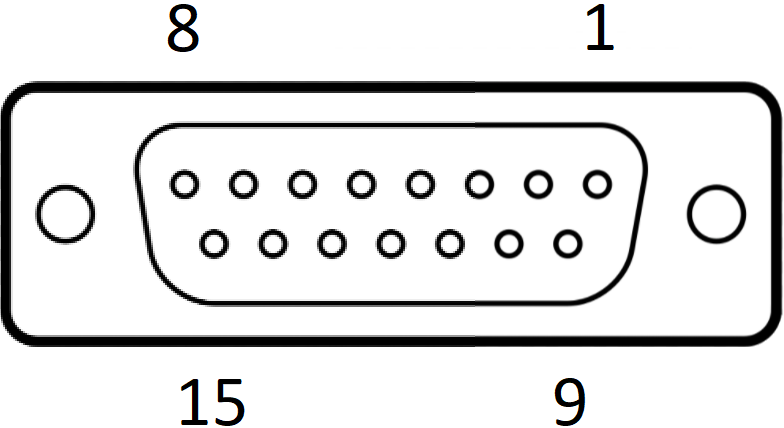

Motor

|

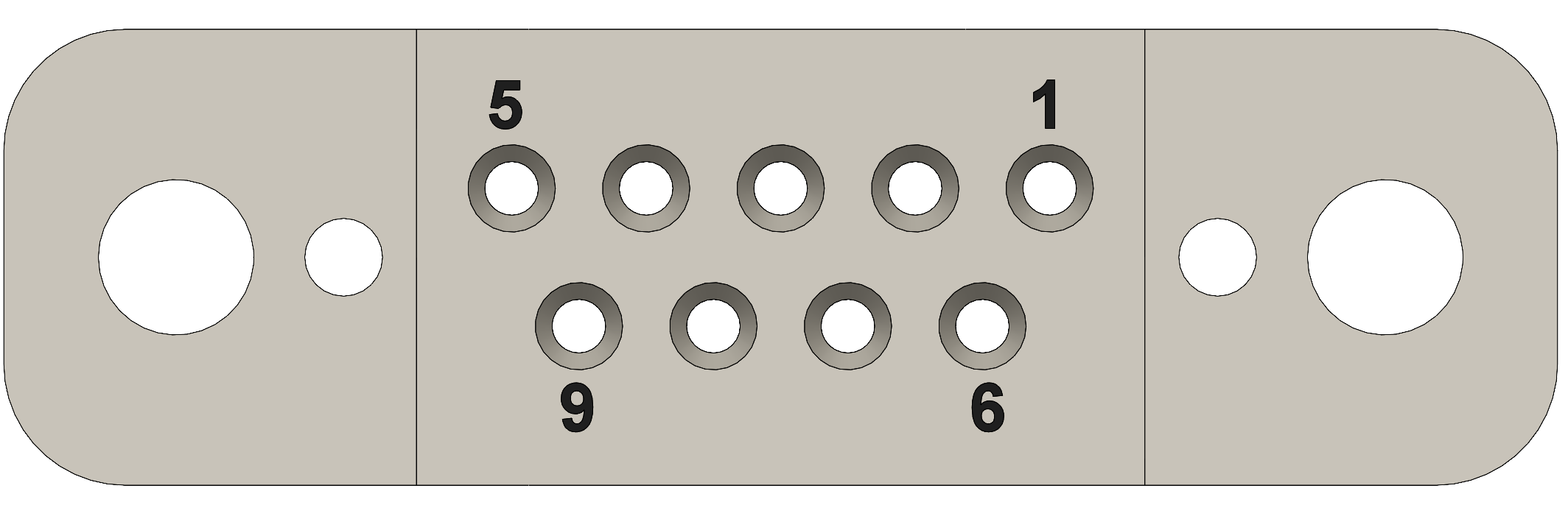

Connector: DA15-F D-Sub, 15 ways, female |

||

|

|

1 | Phase B2 |

| 2 | Phase B1 | |

| 3 | Phase A2 | |

| 4 | Phase A1 | |

| 5 | Limit 1 | |

| 6 | Limit 2 | |

| 7 | Thermocouple negative | |

| 8 | Thermocouple positive | |

| 9 | GND |

|

| 10 | ||

| 11 | ||

| 12 | ||

| 13 | RTD B2 | |

| 14 | RTD B1 | |

| 15 | RTD A | |

DANGER! Danger of electric arcing! Never plug or unplug the connector while powered! Plugging or unplugging motor while powered may damage or destroy the driver output stages.

Motor

Connection of the motor to the vacuum feedthrough, and vacuum feedthrough to the SMD4 is discussed in section Motor Wiring.

Limits

INFORMATION: Limits inputs are duplicated on the I/O connector for maximum user flexibility in arranging wiring for the system. Limit signals on both this and the I/O connector are electrically connected. Do not apply different electrical potentials between like named limits inputs otherwise a short will occur between the two.

Thermocouple

The thermocouple lead for motors equipped with the standard K-Type thermocouple should be connected here. If using a motor equipped with an RTD, this connection may be left open. Be sure to select the correct sensor type, see section Temperature sensor selection.

INFORMATION: To provide greater convenience in wiring to the vacuum chamber, the thermocouple input is included on the motor connector, rather than a dedicated micro K-Type thermocouple connector. This comes at the cost of reduced accuracy due to the parasitic thermocouple junctions that exist within the connector. This is accounted for by the looser accuracy specification for the thermocouple input over the RTD one, and a generous tolerance in the motor over temperature threshold as further insurance. None the less, accuracy can be improved by avoiding large temperature gradients across the SMD4; for example avoid placing the rear panel of the product in direct line of hot exhaust from other equipment.

RTD

For motors equipped with an RTD instead of a thermocouple, make the RTD connection here. If the RTD is not required, leave the connections open.

The RTD input is compensated for cable length by the three wire connection.

Custom cables

Custom motor cables must be built to the following specification to ensure continued compliance with EMC standards and correct function.

General requirements:

- Rated voltage >= 300 V rms, rated current > 1.5 A rms

- Construction; twisted pairs plus overall screen. Foil screen plus drain wire (of same or greater cross sectional area as main cores) acceptable, foil plus braided screen better

- Screen must be connected via as short a wire as possible to a ground pin (pins 9-11) on the connector, using insulated wire

- Maximum cable length is limited by the resistance of the cores; total round trip cable resistance per phase should be kept to less than few ohms. Consult the cable manufacturers data for these details. Excessive cable length causes a reduction in phase voltage at the motor compromising speed/torque characteristics. The RTD circuit is compensated against cable length.

Temperature sensors:

- Use one twisted pair for the thermocouple

- Use one twisted pair for RTD A and B1, and one lead from a second pair for B2

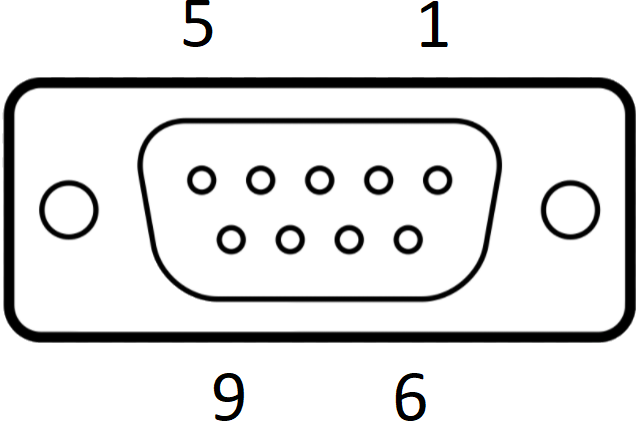

I/O

|

Connector: DE9-F D-Sub, 9 ways, female |

||

| 1 | GND | |

| 2 | Fault (Output, open collector) | |

| 3 | Limit 1/positive | |

| 4 | Enable | |

| 5 | Step | |

| 6 | Reset fault (Input, active low) | |

| 7 | Limit 2/negative | |

| 8 | SDE COM | |

| 9 | Direction | |

Fault output and fault reset

Limits

Duplicated from the motor connector.

Step, direction and enable

The step direction enable interface is an industry-standard interface allowing an external motion controller to generate stepping sequences, bypassing the SMD4’s internal motion controller. The inputs are galvanically isolated with three opto-isolators, and share a common connection, ‘SDE COM’. See section Step/Direction for details.

USB

|

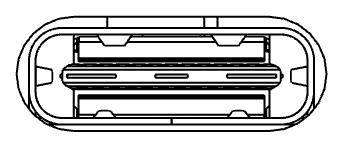

Connector: USB-C |

||

USB Type-C connection. The connection is reversible, and the plug may be inserted either way up.

The SMD4 appears as a virtual COM port when connected to the PC. No additional drivers are required. Configure and control the SMD4 using AML Device Control software, available as a free download from our website at https://arunmicro.com/documents/software/

Alternatively, use a terminal program, or your own application. AML supply a C# API, available on our website to help customers implement their own applications faster.

LAN

|

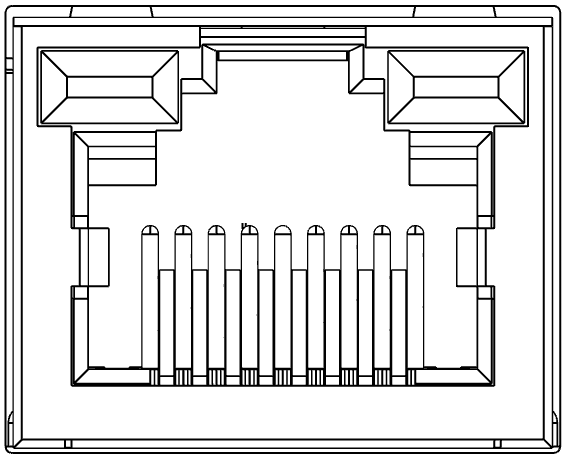

Connector: 8P8C RJ45 RJ45, 8 poles, 8 connections |

||

10/100M network connection with Auto MDI-X.

Configure and control the SMD4 using AML Device Control software, available as a free download from our website at https://arunmicro.com/documents/software/

Alternatively, use a terminal program, or your own application. AML supply a C# API, available on our website to help customers implement their own applications faster.

RS232/485

|

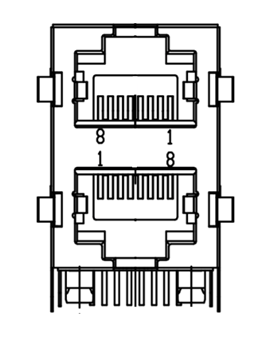

Connector: 8P8C RJ45 RJ45, 8 poles 8 connections |

||

|

|

1 | |

| 2 | ||

| 3 | ||

| 4 | A+/Tx | |

| 5 | B-/Rx | |

| 6 | ||

| 7 | ||

| 8 | GND | |

RS232 and RS485 share pins. Before connecting to them, use an alternate interface (USB or LAN) to configure the desired mode of operation. Undefined behaviour will result if the SMD4 is connected to an RS485 network when in RS232 mode or vice-versa.

There are two identical connectors, allowing SMD4 devices to be daisy-chained together.

An optional termination resistance can be enabled if required. This would typically be enabled on the last device on the bus, to reduce reflections and maintain signal integrity. The usage of this feature should be evaluated in the final system.

Configure the mode of operation (RS232 or RS485) before plugging a connector in. Do not make changes to the mode without first disconnecting both connectors. Undefined behaviour will result if the SMD4 is connected to an RS485 network when in RS232 mode or vice-versa.

Bussing

The dual connectors allow multiple SMD4s (or other devices) to be bussed together. There are several important considerations to be aware of when doing so:

- RS232 is not well suited to multi-drop; use RS485 for this purpose if at all possible. If using RS232, devices can receive and process commands, but will not respond and data cannot be returned to the host.

- Ensure all devices on the bus are in the the same mode (RS232 or RS485) and the same serial configuration (baud rate, etc) matches between devices.

- When using text protocol, begin all commands with the '@' addressing prefix. This places the SMD4 into addressing mode which brings into force alternate communication rules that allow the SMD4 to function properly on a bus with other devices. This is discussed in the Addressing section.

- Do not use text protocol commands without the addressing prefix. This will cause multiple devices to respond at once and the resulting bus contention may result in undefined behaviour.

Front panel

Joystick

|

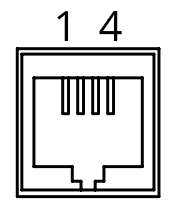

Connector: 4P4C Modular jack |

||

| 1 | GND | |

| 2 | CW | |

| 3 | CCW | |

| 4 | DETECT | |

For connection of a two-button joystick allowing basic motor control, for example, during commissioning. AML supply the SMD3 Joystick, part number ‘SMD3JOY’, which is compatible with the SMD3, for this purpose. The SMD4 can be configured to automatically switch to joystick mode on connection of the joystick. See AUTOJS.

If designing your own joystick or device to connect to this port:

- Inputs have internal pull-ups

- Activate the function by shorting ‘CW’, ‘CCW’ or ‘DETECT’ to pin 1, ‘GND’

- ‘DETECT’ is used to signal to the SMD4 that the joystick is connected and trigger automatic switch to joystick mode (if configured). If this functionality is not required, leave the pin unconnected.

Logic level signals may also be used; 12 V max.

Status indicators

The fault indicator flashes or remains lit if the SMD4 is in a fault state (see section Faults for fault indications). When a fault is present, motor operation is disabled.

Motor wiring

Overview

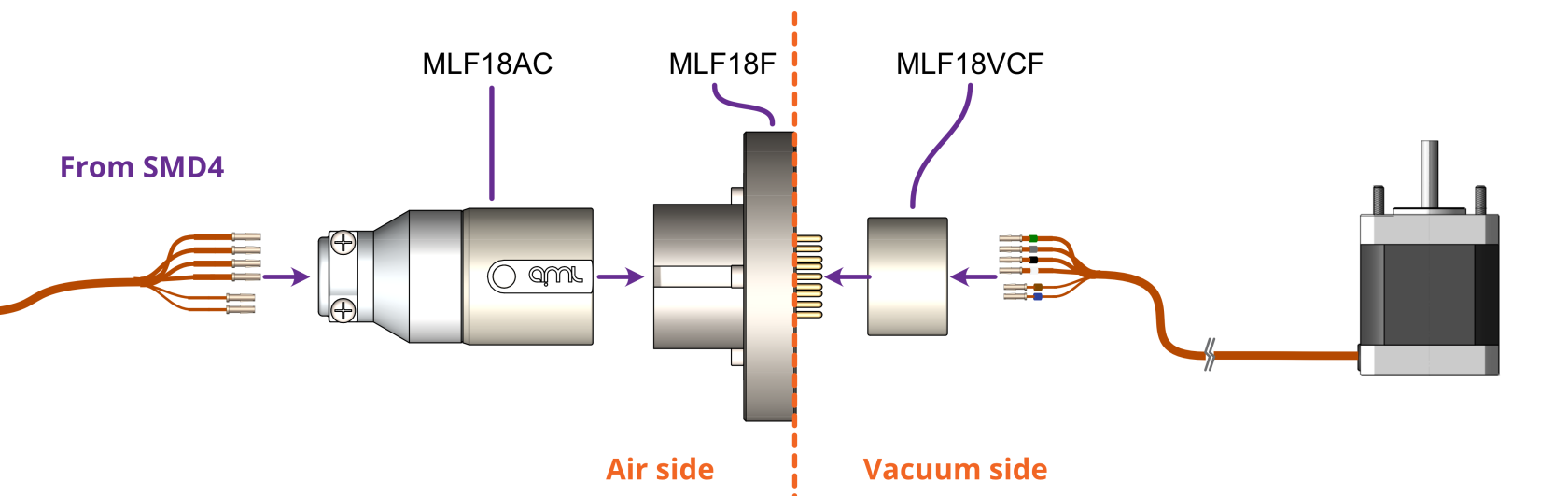

Connecting motors inside a vacuum chamber to the SMD4 comprises two tasks:

-

Wiring the motor to a vacuum feedthrough installed in the chamber wall.

-

Wiring the vacuum feedthrough to the SMD4.

AML supply vacuum feedthroughs, ready-made cabling, and components allowing custom cables to be easily manufactured. A typical setup is shown below and used for illustration throughout this section.

INFORMATION: Verify that the motor is working correctly before sealing the vacuum chamber. Rectifying mistakes afterwards is inconvenient.

Lead identification

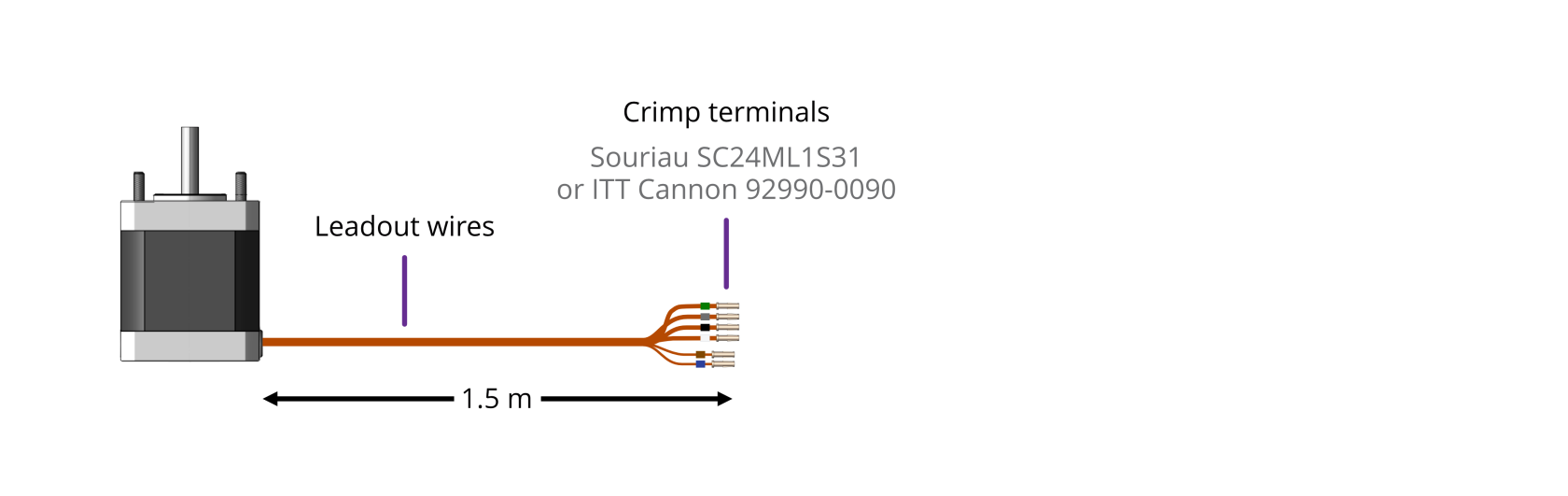

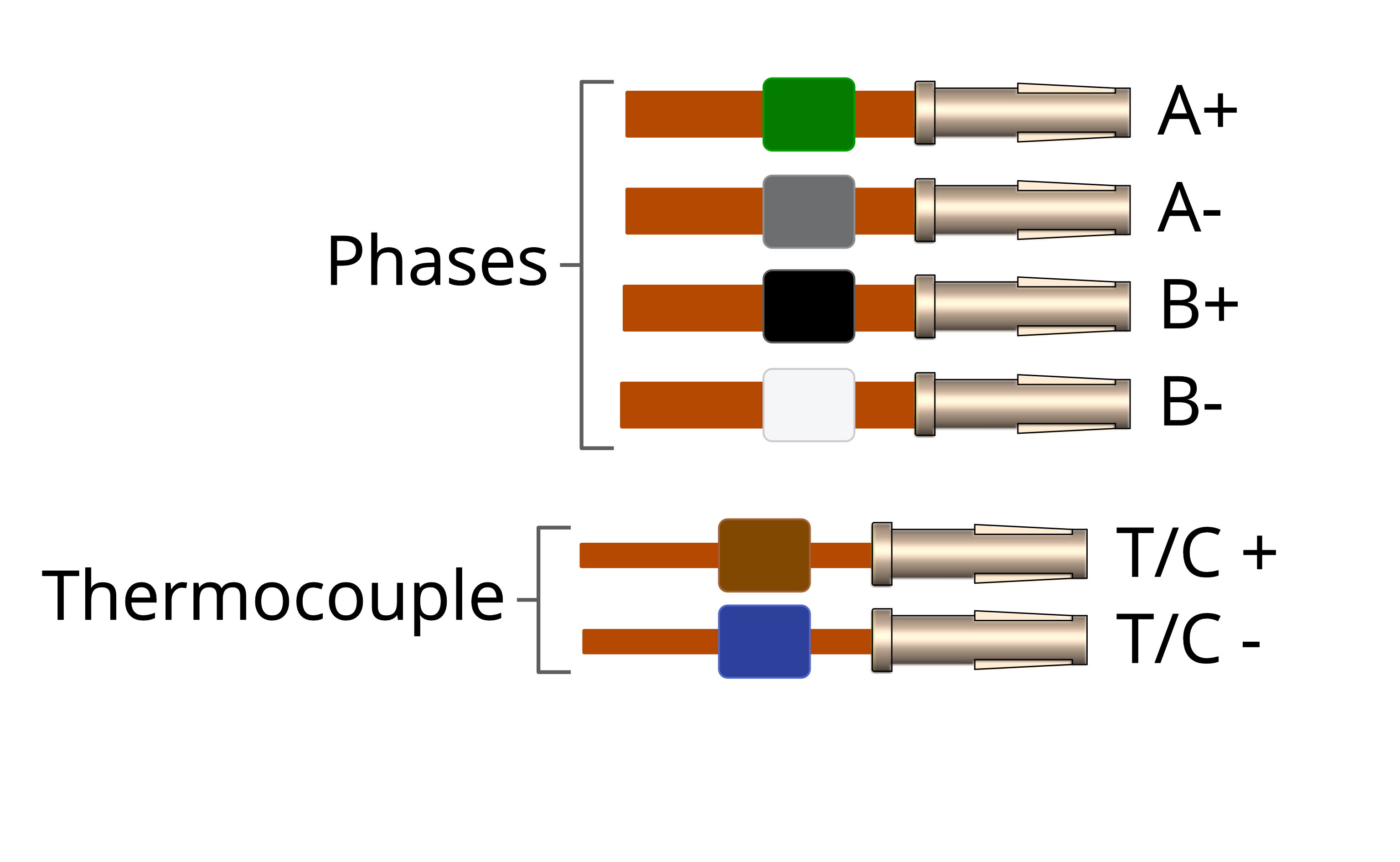

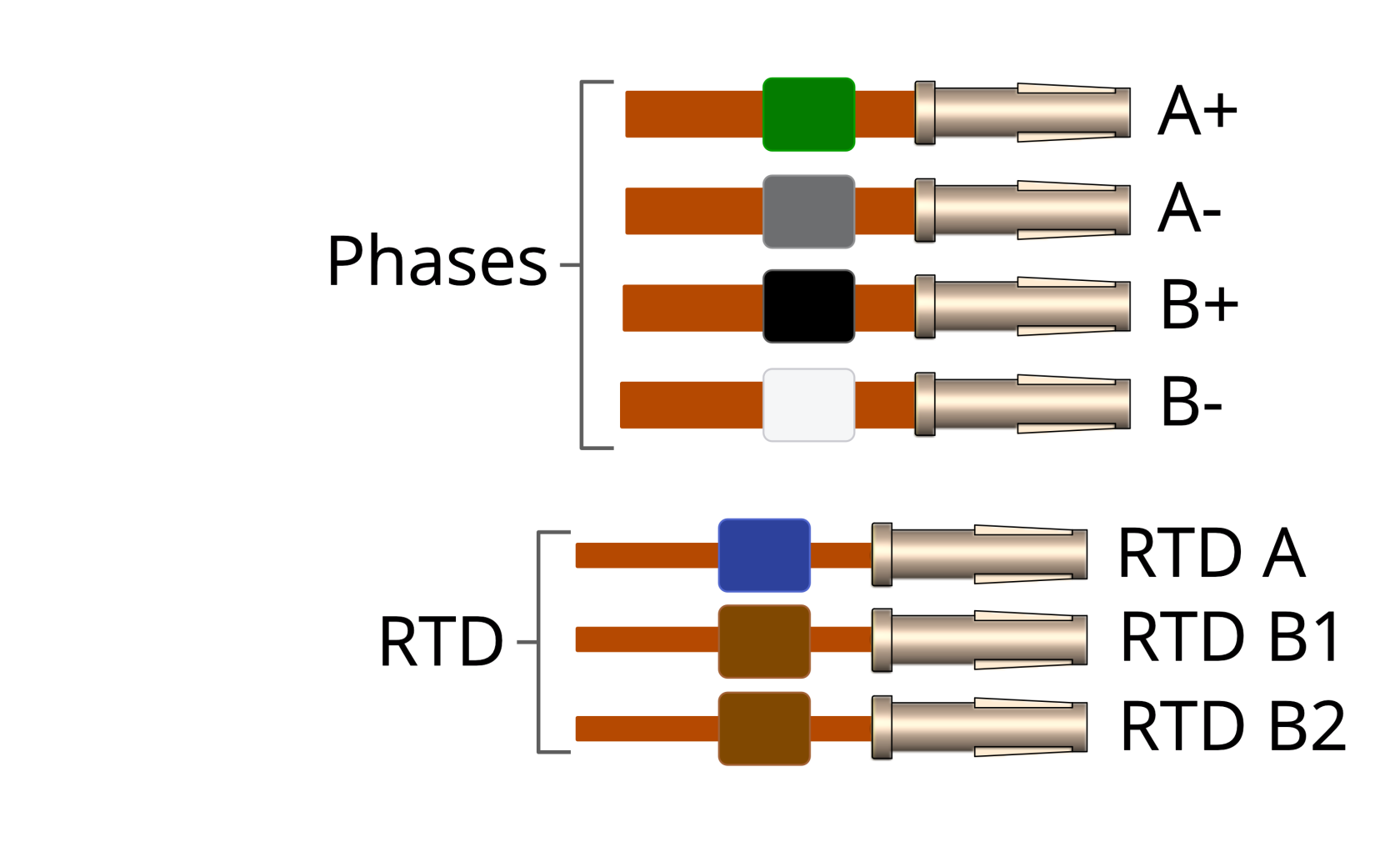

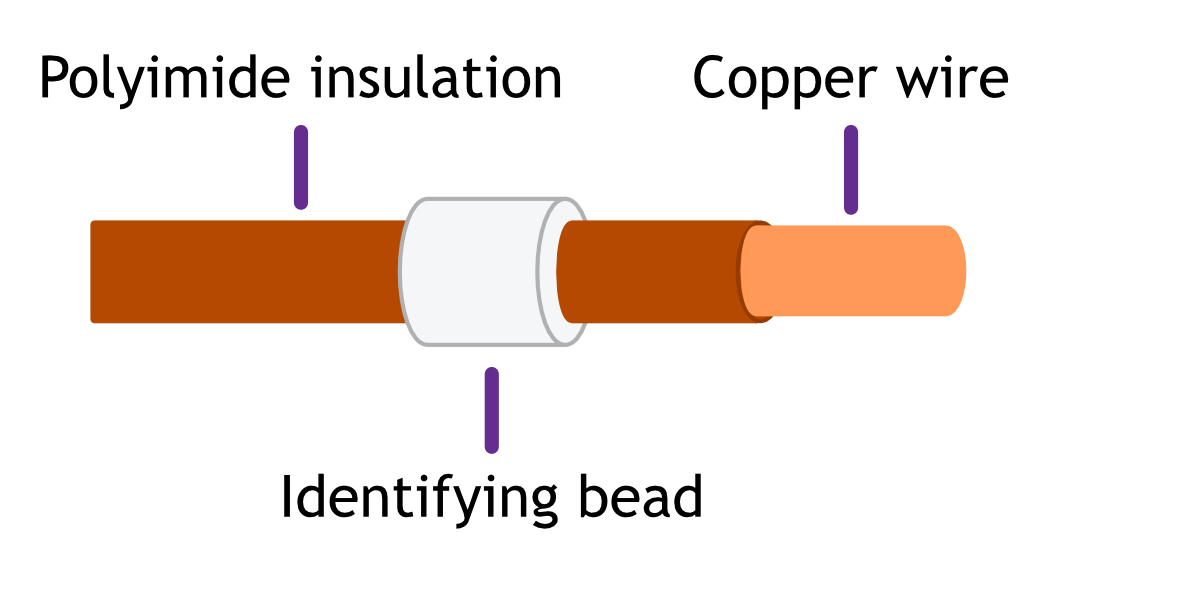

The motor leadout wires are self-coloured polyimide film-wrapped, silver-plated OFHC solid copper and each is fitted with a 1.5 mm crimp socket terminal. They are supplied fitted with UHV compatible coloured glass beads for identification. The phase leadout wires are much thicker than the thermocouple leadouts. The leadout wires of each phase should be twisted together.

| Motors equiped with a Thermocouple: | Motors equiped with an RTD: |

|

|

If the identification beads have been removed, the wires can be identified using an inexpensive multimeter, and a magnet. The multimeter must be capable of measuring resistance with a resolution of about 1 ohm.

|

Thermocouple Leadouts The thermocouple wires are much thinner than the phase leads, and there are two of them. If three wires are present, the motor has an RTD installed, see below for details. The thermocouple is insulated from the rest of the motor. |

|

|||||||||

|

RTD Leadouts As per the thermocouple leads, but three instead of two leads. These must be identified by resistance; one pair of wires are connected at the motor end. These will measure a few ohms depending on cable length and are the ‘B1’ and ‘B2’ connections, which are interchangeable. The remaining wire is the ‘A’ connection and should measure around 100 ohms to either ‘B1’ or ‘B2’. |

|

||||||||||||

Phase leadouts

These are the four thicker leadouts. Identify the two motor phases by their resistance, which will be in the range of 3 to 15 ohms, depending on the motor type. There is no electrical connection between the two phases, to the thermocouple/RTD or the case of the motor. Most of the resistance is in the windings of the motor and is virtually unaffected by shortening of the leads. Connect each phase to the appropriate drive terminals. The resistance of the wires from the feedthrough to the drive must be less than a few ohms.

Note regarding reversal of rotation

Upon completion of wiring, there is a 50 % probability that the direction of rotation will be reversed from the desired or conventional sense. To rectify this, exchange the connections to one of the phases. For example, locate the Phase A + and Phase A – connections, and swap them around. This can be done on air or vacuum side while the chamber is still open.

Wiring motor to a vacuum feedthrough

AML supports the MLF18 feedthrough or a standard D-Sub feedthrough.

9-Way D-Sub Female

The VC9D-40CF 9-way D-Sub male feedthrough is suitable for one motor fitted with either a thermocouple or 3-wire RTD. The standard crimp terminals supplied with AML motor leadout wires should be removed and replaced with a VC9DF PEEK D-Sub female connector and crimp terminals. An optional VC9DB cable strain relief is also available.

Motor wires pinout for the VC9DF

| Connection | Colour | Pin | Pin Insertion Side |

| Phase A1 | Green | 4 |  |

| Phase A2 | Grey | 3 | |

| Phase B1 | Black | 2 | |

| Phase B2 | White | 1 | |

| Thermocouple + | Brown | 8 | |

| Thermocouple - | Blue | 7 | |

| RTD A | Blue | 5 | |

| RTD B1 | Brown | 6 | |

| RTD B2 | Brown | 9 |

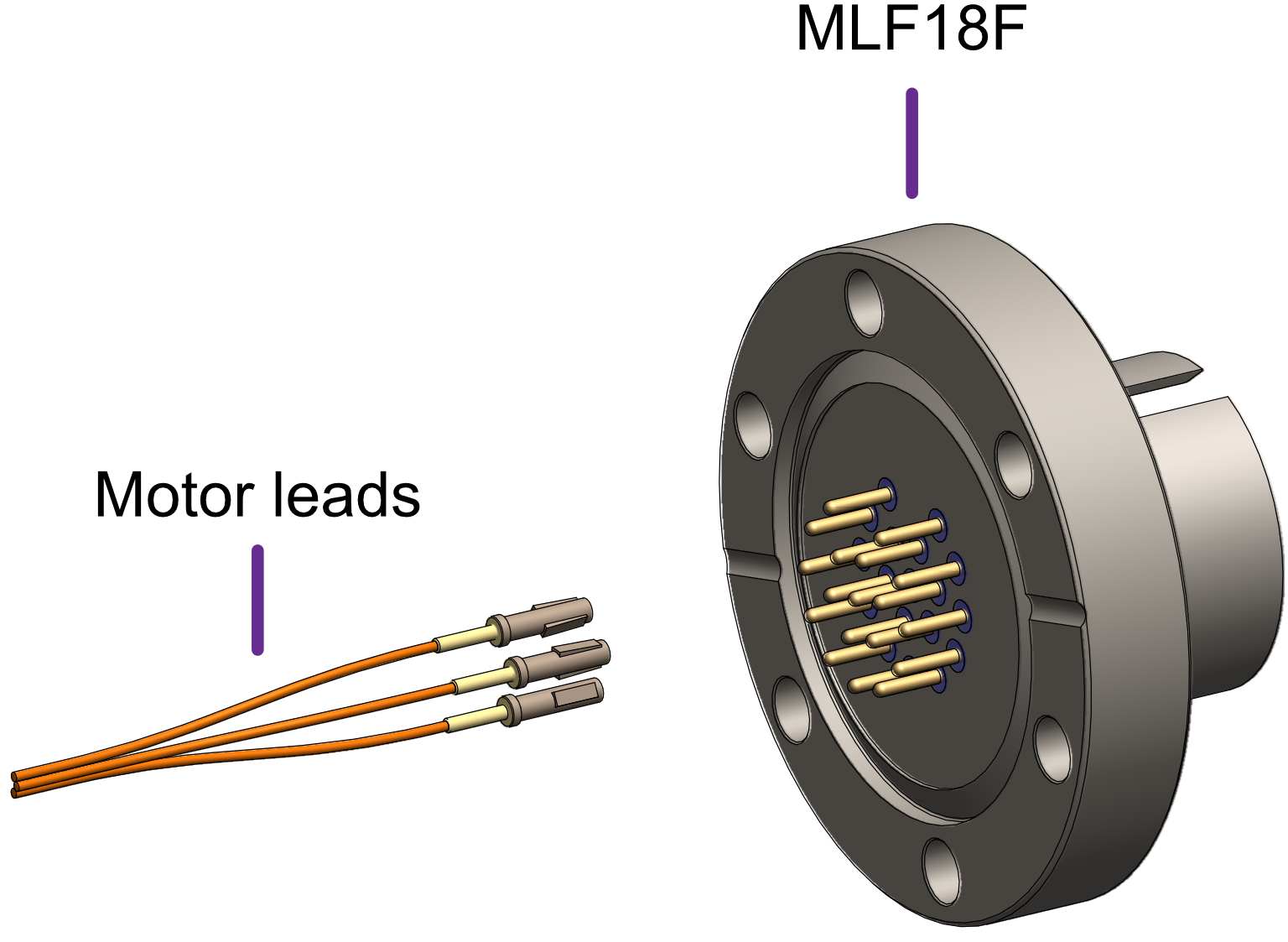

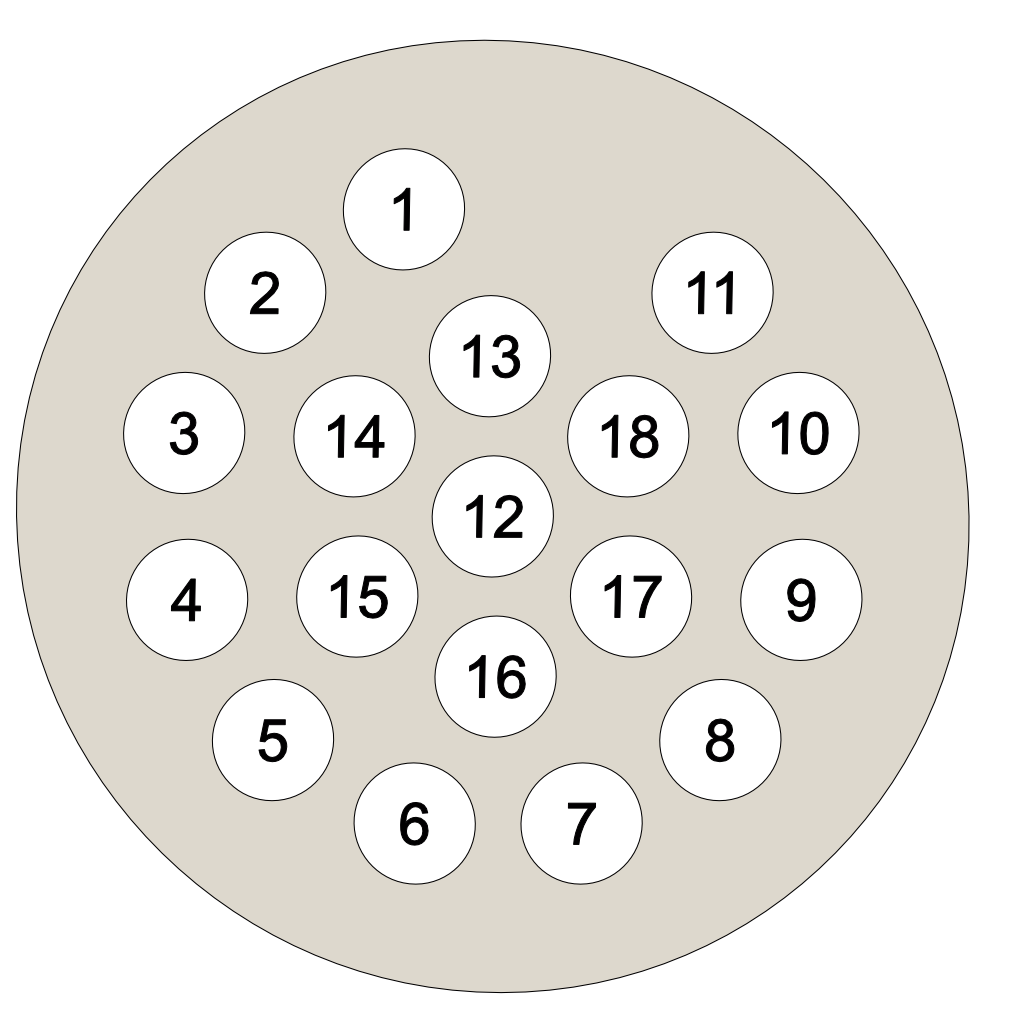

18-Way MLF18

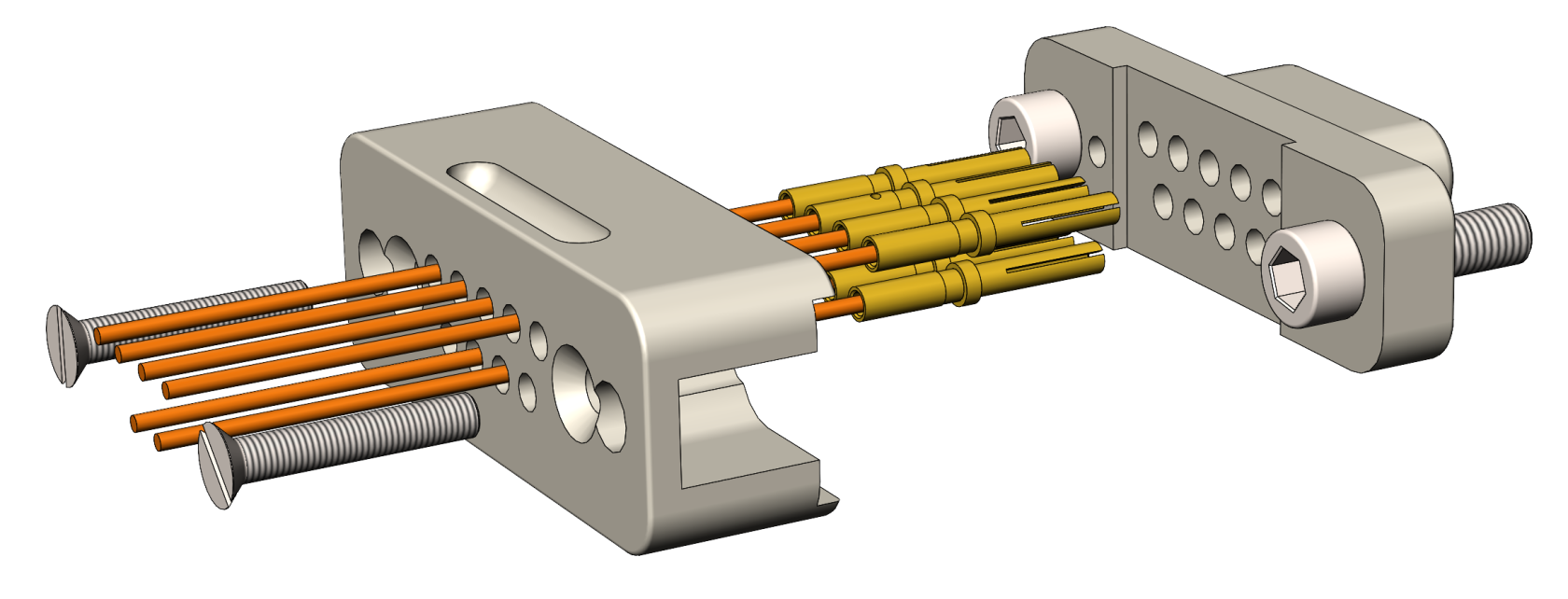

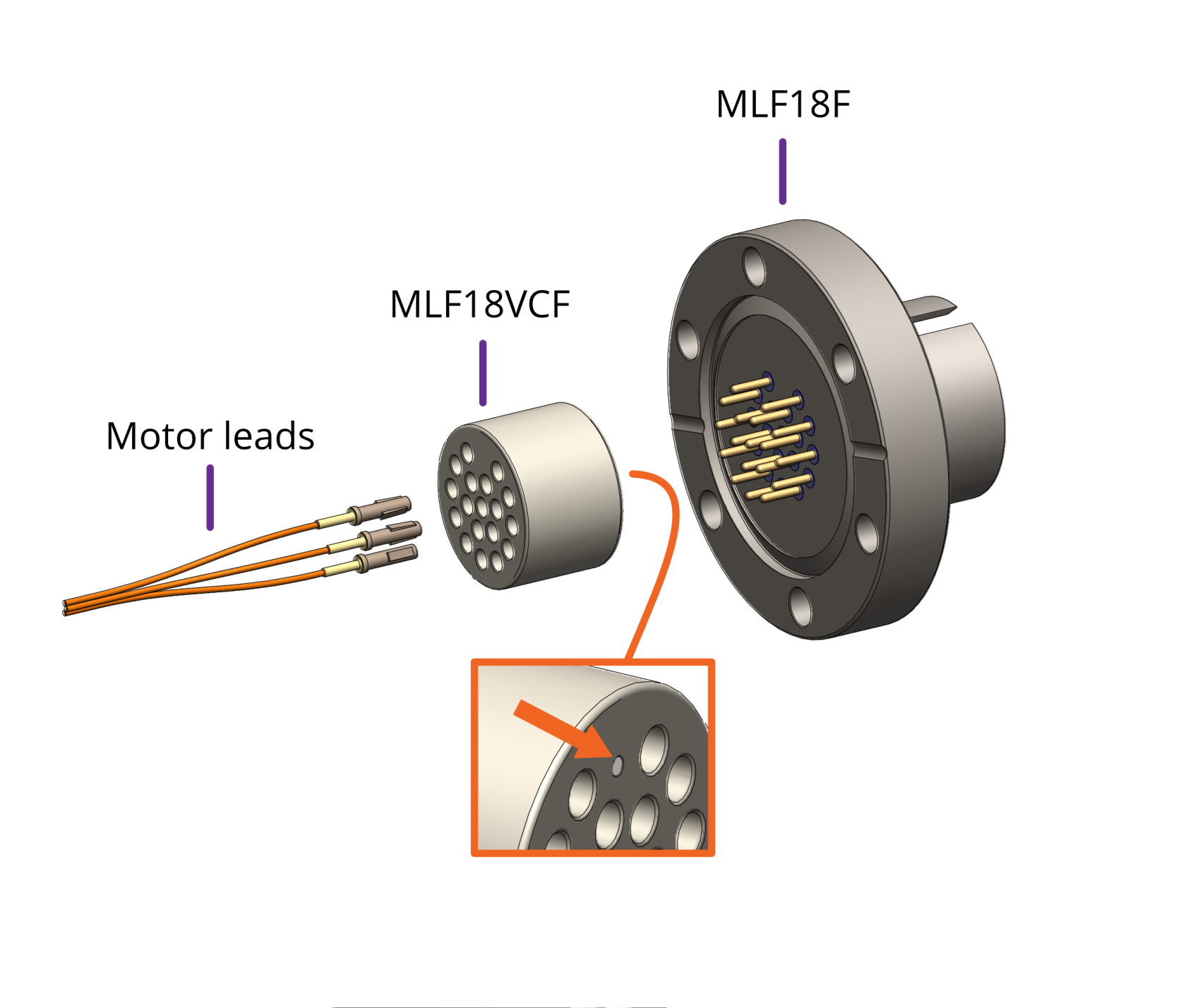

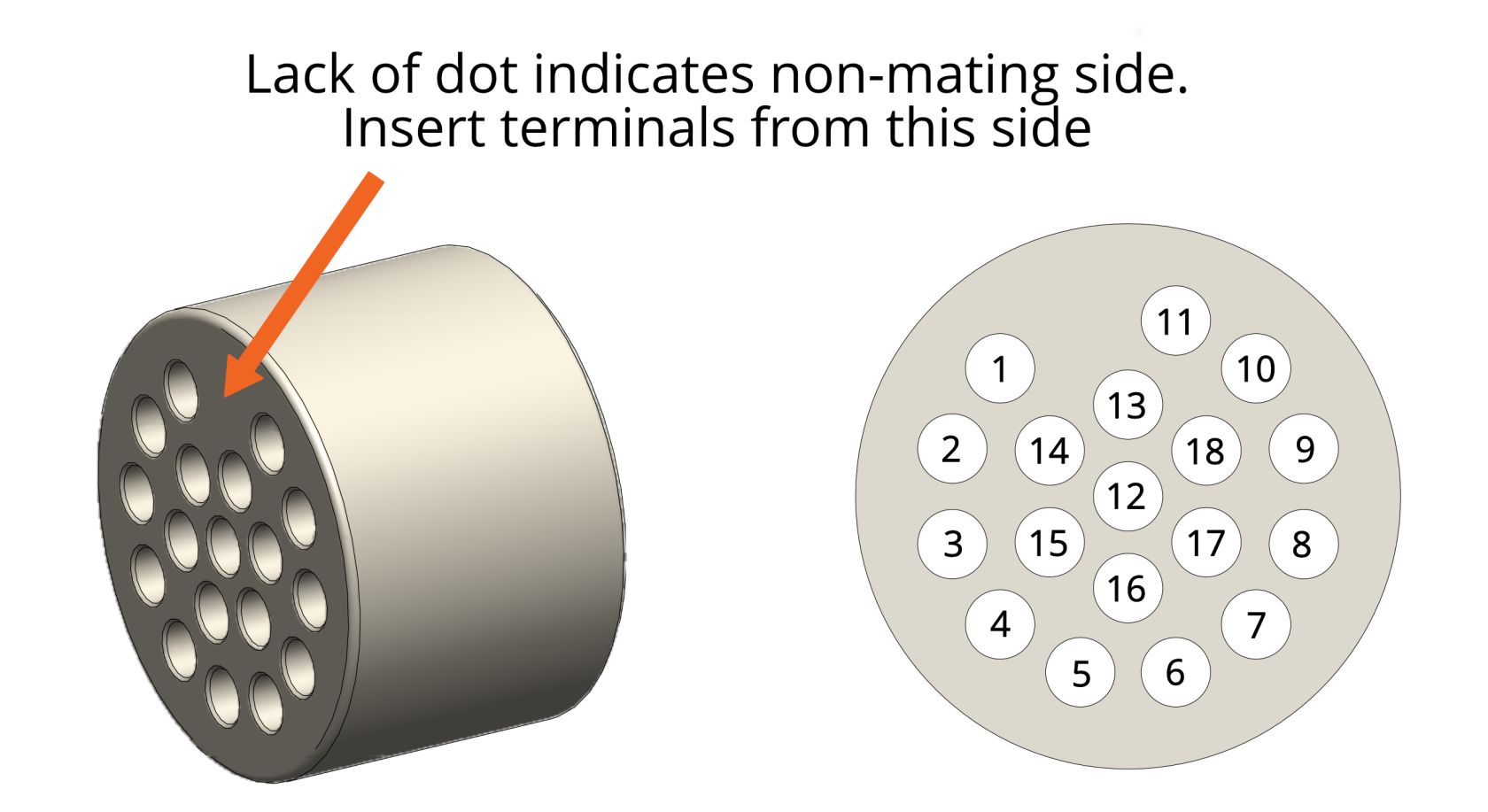

The MLF18F feedthrough has 18 x 1.5 mm gold-plated feedthrough pins and is suitable for up to three motors fitted with thermocouples or up to two motors fitted with 3-wire RTDs. An internal bakeable connector, MLF18VCF, is available into which the crimp terminals on the motor leads are inserted. This significantly reduces the risk of short-circuits and makes the installation more convenient.

| Using the MLF18F feedthrough and MLF18VCF vacuum side connector: | Alternatively, plug crimps directly onto the feedthrough pins of the MLF18F: |

|

|

|

| Mating side identified by dot. Motor lead terminals should be inserted in the other side. |

Using other feedthroughs

AML stepper motors can be ordered with either a K-Type thermocouple, or 3-wire PT100 RTD. The former requires 6 pins, and the latter 7 pins.

When using motors installed with a thermocouple, it is not necessary to use a thermocouple vacuum feedthrough or extension wires, as the error introduced by incompatible feedthrough material is usually less than 5 °C and the temperature measurement is not required to be very precise.

| Preparation of motor leadouts for connection to other feedthroughs | |

|

If making custom terminations for the motor leads, the installed crimps must be removed, and the wire ends stripped of insulation. Standard motors are fitted with Polyimide film-wrapped leads (illustrated below), and radiation-hard motors are fitted with polyimide enamelled leads.

Polyimide is strong, flexible and abrasion-resistant and therefore difficult to strip. The simplest method of stripping polyimide film is to cut a ring with a sharp knife and withdraw the cylinder of insulation over the end of the wire. Be careful not to mark the conductor surface with the knife. Strip the enamelled radiation-hard leads by scraping with a sharp knife. Either type of lead may be stripped with a suitable high-speed rotary stripper. Do not use a thermal stripper. |

|

Wiring between drive and vacuum feedthrough

AML supply three standard SMD4 cables. These are:

CAB-D15D9: 3 metres long. D-sub 15-way male connector for connecting to the SMD4. D-sub 9-way female connector for connecting to a feedthrough, such as AML's VF9D-40CF.

CAB-D15MLF: 3 metres long. D-sub 15-way male connector for connecting to the SMD4. MLF18AC connector for connecting to AML's MLF18F feedthrough.

CAB-3D15MLF: 3 metres long. 3x D-sub 15-way male connectors for connecting up to 3 separate SMD4s. MLF18AC connector for connecting to AML's MLF18F feedthrough.

Alternatively, AML supply multiple air-side connectors which can be used to make custom leads to mate with the MLF18F or D-sub electrical feedthroughs. These are supplied with a kit that includes the crimps as well as instructions for their use.

Leads between the MLF18AC and SMD4 should be assembled according to the following guidance for safe, reliable operation and continued compliance with EMC standards.

Cable requirements

- Quantity of cores as required; (one motor requires 6 cores when fitted with a thermocouple, or 7 if fitted with an RTD). The cable must be screened. A foil screen plus drain wire is acceptable; a foil plus braid screen is better.

- The screen must be connected via as short a wire as possible to pin 1, ‘GND’ of the motor connector, using insulated wire.

- Rated voltage >= 300 V rms

- Rated current > 1.5 A rms

- Cable cores must be twisted together in pairs, using one pair per phase, one pair for the thermocouple, and a group of three for the RTD. This reduces radiated emissions from the cable and improves immunity of the RTD and thermocouple signals to the motor.

- Maximum cable length is limited by round trip resistance, which should be less than a few ohms. Review cable manufacturer's data to obtain this figure.

Wiring up to the MLF18AC airside connector

The MLF18AC is supplied with comprehensive instructions detailing correct usage of the connector. The pinout to match with the standard MLF18F + MLF18VCF pinning described in section Motor wiring is shown below. Note that the illustration shows the MLF18AC looking into the non-mating side of the connector, i.e. the side into which crimps are inserted.

|

Looking into the non-mating face of the MLF18AC, into which crimps are inserted |

||||||||||||||||||||||||||||||||||||||||

|